This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Leistungsspektrum

We offer EVERYTHING from one source

Customized operating material and processes for different requirements and areas

The Autmaring Engineering GmbH considers itself a Full-Service Partner in terms of customized operating material and electronic as well as mechanical processes for different requirements and fields of activity.

We offer a large range of services which is mirrored in our advanced and efficient machine park which can master everything. We ensure precisely tailored results and on-schedule handling from the beginning.

Everything is part of a value chain, so that we normally don’t have to outsource any production processes to other companies. Our holistic project management promises to satisfy different customer wishes and to complete all tasks and requirements we receive. We manufacture everything made to measure and according to your individual wishes.

Do you have any questions? Then write to us or call us without obligation. We are looking forward to your project.

Modernste Technik und höchste Anforderung

an Form und Lagetoleranzen

Der entscheidende Schritt vom fertigen Design zum ersten Bauteil liegt in einem maßgeschneiderten Fertigungskonzept. OEM-gerechtes fertigen an leistungsfähigen CAD- und CAM-Arbeitsplätzen und verschiedenen Spritzgieß- und Bearbeitungssystemen sowie Einrichtungen zur Herstellung von Graphitelektroden, garantieren eine effiziente und kostensparende Produktion in höchster Qualität und Güte.

Neue Simulationstechnologien ermöglichen es uns, bereits in einem frühen Entwicklungsstadium Gutachten über die Herstellbarkeit Ihres Produktes zu erstellen. Spätere Produktionsprobleme werden so frühzeitig erkannt oder vermieden. Die Kosten für Prototypen und Tests werden reduziert.

Tailor-made solutions for individual customer wishes

We manufacture a large number of devices and machines – from simple systems for prototypes to complex large series solutions. These are especially for aluminum structural component finishing. We cover everything from the first prototype to the series and we are capable of fulfilling individual wishes of our clients. No matter if a client asks for a milling or robot welding device – there are no limits set to our skills and your wishes. We manufacture customized and matching components which are characterized by their robustness and durability. We follow certain guidelines, such as, precision, reliability as well as easy handling during the construction of devices and plants. We consider ever new task to be a positive challenge and we offer diverse solutions to our clients requirements.

Thanks to our know-how and our large machine park, we are able to find a solution even for the most complex problems, no matter if it’s about processing-, welding- or mounting devices, teachings, hammer forms, or forming tools. We work with modern 5-axis-CnC machining centers and we manufacture workpieces with a very high degree of precision and quality through the aid of innovative measuring technology and software.

We create products from your ideas

We are specialists in terms of developing and manufacturing high-quality plastic components with the help of innovative technology and software. Our machine park consists of the most modern and efficient production machines on the market which allows a large range of production possibilities, depending on your demands.

Our focus lies on the production of technical components. As ONE-STOP-PARTNER we are not limited to the pure casting process for the manufacturing of fitting parts but we also use machining manufacturing methods. Our business and production processes distinguish themselves from others thanks to reverse engineering, sample/ prototype and small series manufacturing as well as project management which is made available to you until the very last step of the production.

Machine park

650 t Cosing force

300 t Cosing force

175 t Cosing force

90 t Cosing force

65 t Cosing force

3 x 50 t Cosing force

Series and prototype production

We work with state-of-the-art 5-axis CNC machines. This is a great advantage because it allows us to produce extremely complicated machine parts that would otherwise have to be cast - which not only saves time but also costs and has a positive effect on the quality of the parts due to the machining in throughput.

- Material movement with 10t Crane

- Chiron Mill FX 800

- Chiron Mill FX 2000

- Chiron Mill FX 800 with automation

- OPS Ingersoll Eagle V5 (interlinked with placement robot)

- OPS Ingersoll Eagle V9 (interlinked with placement robot)

- Hermle C 400

In the same way, we also work with innovative eroding and grinding technology.

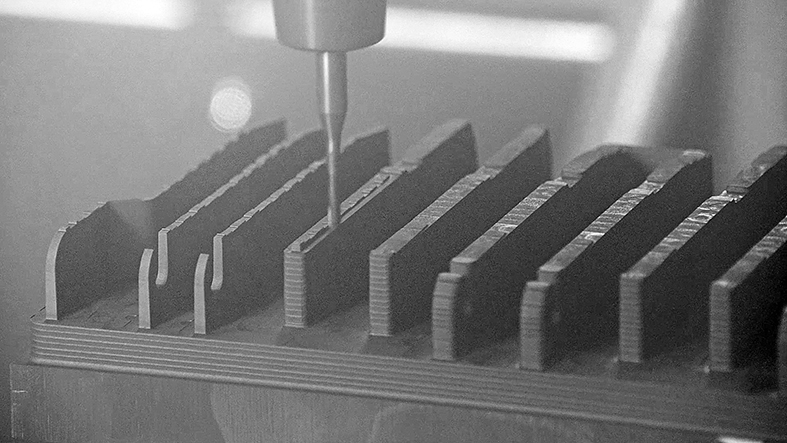

Production of graphite electrodes

Full-Service-Dienstleister in der Graphitelektrodenherstellung

Autmaring Engineering GmbH sees itself as a full-service partner, which is also reflected in our electrode production. In this part of our production we create graphite electrodes on precise dynamic CNC machines of the brand OPS-Ingersoll. We ensure process consistency by using the EROWA ITS holder system in conjunction with RFID chip systems. On this basis, we manufacture fully automatically and efficiently. Translated with www.DeepL.com/Translator (free version)

OPS Ingersoll Eagle V5

OPS Ingersoll Eagle V9

Automation technology. HMI for electronic and mechanical systems

As a full-service partner in the control and automation technology, we have many satisfied customers and many successfully finished projects. We develop customized solutions for process automation of electronic and mechanical systems and we are major talents in the human machine interface (HMI) field, or better said, in the creation of a suitable operation interface between humans and machines.

We know how to make the especially complex mechanical processes in control technology easy to use and user-friendly. In this way, we offer in the field of mobile and industrial automation easy-to-use and menu-driven handling of complex operating and machine procedures that’s why it’s important to us to develop devices which illustrate the easy-to-use menu navigation and the self-explaining interface.

A user-friendly handling of control units saves valuable time and costs and is the most important tool in the end with which users and those responsible can coordinate and control process and production flows.

We offer a wide spectrum of competence in the field of measurement and control technology. For instance, we can check the efficiency of your plastic components and other technical elements in a fully air-conditioned room by using our stationary measuring units and a 3D coordinate measuring machine of type Fa. Wenzel. The previously specified parameters of the to be measured unit get checked as well as the tolerances within the nanostructure. We can guarantee an outstanding product quality and prevent unnecessary optimization loops thanks to such a sensor-based technology. Furthermore, we have the possibility to take CAD-based three-dimensional measurements on-site thanks to our mobile Faro Prime Measurement Arm.

We can also design and implement customized measurement systems for your serial products and production flows ourselves, for instance, in cases where a measuring device is needed for special production parts. We place the parts into the device and the sensor checks them and their efficiency by scanning their neuralgic points. After we have created a sample with standard values, we can evaluate if the production of the component was successful or if we need to sort out the component. In this way, we don’t just create a smooth and fast process flow but we also guarantee a consistent product quality. Through the aid of highly sensitive sensors we can scan each component at selected points. If parts differ from the standard size, we will repair or replace them, if necessary. We are experts in this sensor-based technology and develop individual manufactured measuring equipment solely for our clients products.

Messtechnik stationär

3D Koordinatenmessmaschine

LH87/ Fa. Wenzel

Arbeitsbereich 1000x760x660mm

Messtechnik mobil

-

- Mobile measurement technology by means of Faro Prime measuring arm

- CAD-based, three-dimensional measurement also at your site

- Software: CAM2 Measure 10 for maximum measurement efficiency

- Faro arm with 2.4m working space and a measurement repeatability of 0.02mm

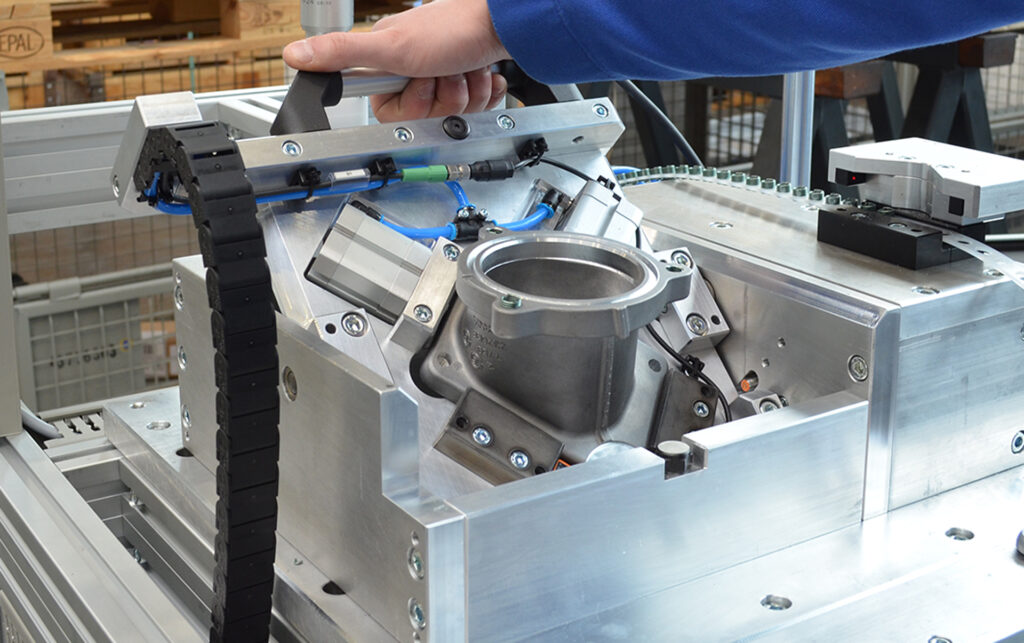

Greater efficiency through compression of various, individual work steps in a compact automation unit

We manufacture customized machines and systems according to specific requirements and individual wishes, so that you get complex tasks and processes automated in one working unit. We either design and manufacture completely new machines or make extensive modifications to existing machines. We build new products completely in our own factory. We analyze the task / sample piece in advance and develop precisely fitting solutions. From single components to complete solutions, you can expect no hidden or unexpected costs. Translated with www.DeepL.com/Translator (free version)

Any questions? Ask! - We accompany you on your way to more productivity

Our range of services

We offer EVERYTHING from one source

Customized operating material and processes for different requirements and areas

The Autmaring Engineering GmbH considers itself a Full-Service Partner in terms of customized operating material and electronic as well as mechanical processes for different requirements and fields of activity.

We offer a large range of services which is mirrored in our advanced and efficient machine park which can master everything. We ensure precisely tailored results and on-schedule handling from the beginning.

Everything is part of a value chain, so that we normally don’t have to outsource any production processes to other companies. Our holistic project management promises to satisfy different customer wishes and to complete all tasks and requirements we receive. We manufacture everything made to measure and according to your individual wishes.

Do you have any questions? Then write to us or call us without obligation. We are looking forward to your project.

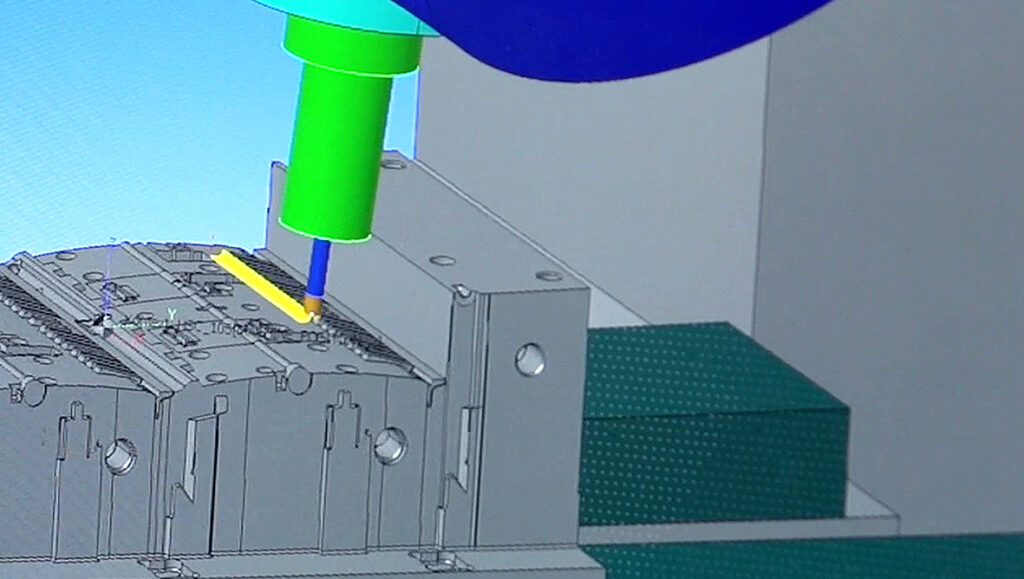

Modern technology and high requirements towards form and position tolerance

A customized production process is the crucial step from a finished draft to the first component. Our OEM construction method as well as the work with high-performance CAD and CAM positions, different injection moulding and cutting machines, and machines for the manufacturing of graphite electrodes guarantee an efficient and a cost saving production at a high quality.

At an early stage, innovative simulation technologies give us the possibility to find out if your product can be produced. Potential production problems that could arise at a later stage, are identified and avoided in time. The costs for prototypes and tests are reduced.

Tailor-made solutions for individual customer wishes

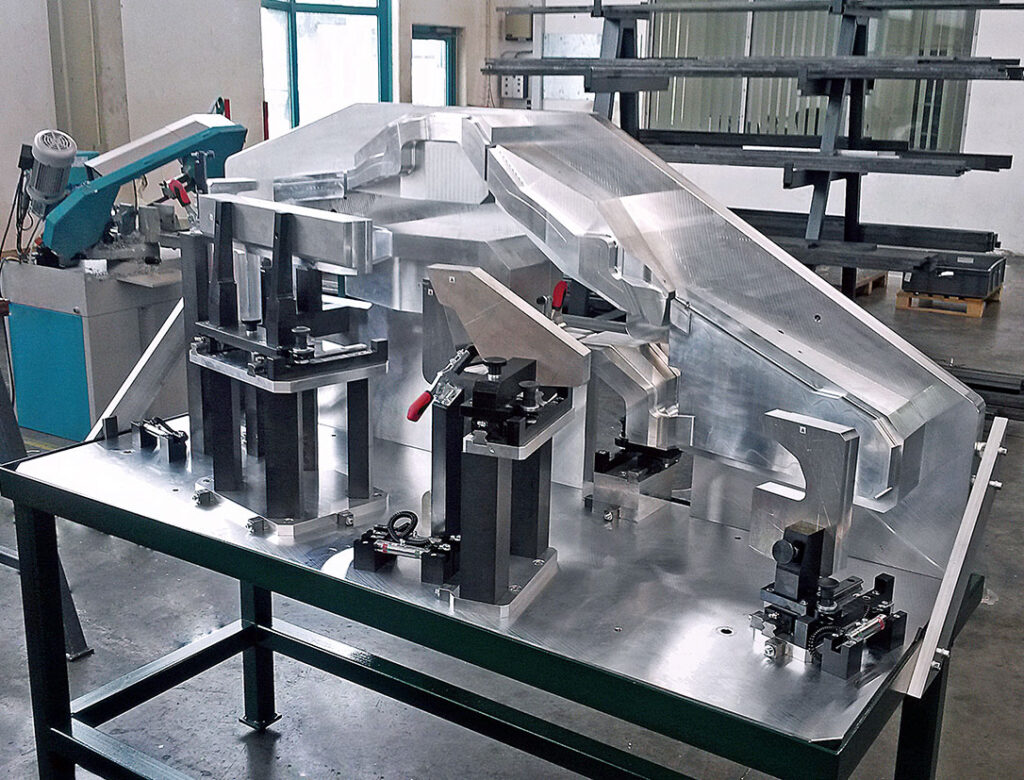

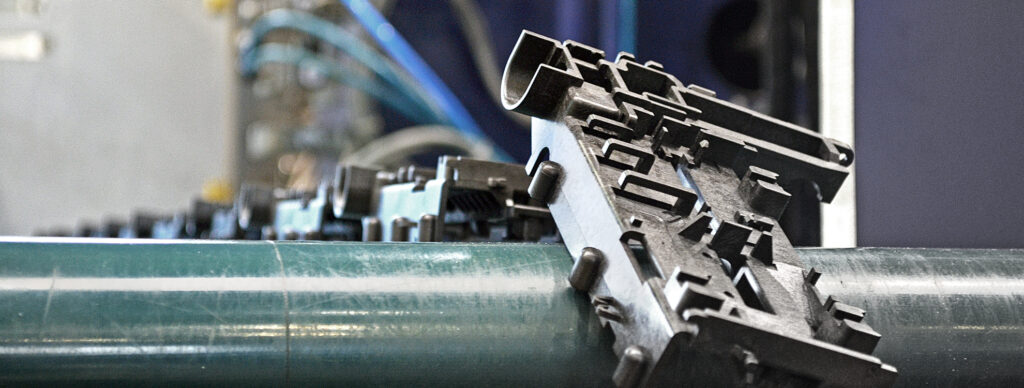

We manufacture a large number of devices and machines – from simple systems for prototypes to complex large series solutions. These are especially for aluminum structural component finishing. We cover everything from the first prototype to the series and we are capable of fulfilling individual wishes of our clients. No matter if a client asks for a milling or robot welding device – there are no limits set to our skills and your wishes. We manufacture customized and matching components which are characterized by their robustness and durability. We follow certain guidelines, such as, precision, reliability as well as easy handling during the construction of devices and plants. We consider ever new task to be a positive challenge and we offer diverse solutions to our clients requirements.

Thanks to our know-how and our large machine park, we are able to find a solution even for the most complex problems, no matter if it’s about processing-, welding- or mounting devices, teachings, hammer forms, or forming tools. We work with modern 5-axis-CnC machining centers and we manufacture workpieces with a very high degree of precision and quality through the aid of innovative measuring technology and software.

We create products from your ideas

We are specialists in terms of developing and manufacturing high-quality plastic components with the help of innovative technology and software. Our machine park consists of the most modern and efficient production machines on the market which allows a large range of production possibilities, depending on your demands.

Our focus lies on the production of technical components. As ONE-STOP-PARTNER we are not limited to the pure casting process for the manufacturing of fitting parts but we also use machining manufacturing methods. Our business and production processes distinguish themselves from others thanks to reverse engineering, sample/ prototype and small series manufacturing as well as project management which is made available to you until the very last step of the production.

Machine park

650 t Cosing force

300 t Cosing force

175 t Cosing force

90 t Cosing force

65 t Cosing force

3 x 50 t Cosing force

Series and prototype production

We work with state-of-the-art 5-axis CNC machines. This is a great advantage because it allows us to produce extremely complicated machine parts that would otherwise have to be cast - which not only saves time but also costs and has a positive effect on the quality of the parts due to the machining in throughput.

- Material movement with 10t Crane

- Chiron Mill FX 800

- Chiron Mill FX 2000

- Chiron Mill FX 800 with automation

- OPS Ingersoll Eagle V5 (interlinked with placement robot)

- OPS Ingersoll Eagle V9 (interlinked with placement robot)

- Hermle C 400

In the same way, we also work with innovative eroding and grinding technology.

Production of graphite electrodes

Full-Service-Dienstleister in der Graphitelektrodenherstellung

Autmaring Engineering GmbH sees itself as a full-service partner, which is also reflected in our electrode production. In this part of our production we create graphite electrodes on precise dynamic CNC machines of the brand OPS-Ingersoll. We ensure process consistency by using the EROWA ITS holder system in conjunction with RFID chip systems. On this basis, we manufacture fully automatically and efficiently. Translated with www.DeepL.com/Translator (free version)

OPS Ingersoll Eagle V5

OPS Ingersoll Eagle V9

Automation technology. HMI for electronic and mechanical systems

As a full-service partner in the control and automation technology, we have many satisfied customers and many successfully finished projects. We develop customized solutions for process automation of electronic and mechanical systems and we are major talents in the human machine interface (HMI) field, or better said, in the creation of a suitable operation interface between humans and machines.

We know how to make the especially complex mechanical processes in control technology easy to use and user-friendly. In this way, we offer in the field of mobile and industrial automation easy-to-use and menu-driven handling of complex operating and machine procedures that’s why it’s important to us to develop devices which illustrate the easy-to-use menu navigation and the self-explaining interface.

A user-friendly handling of control units saves valuable time and costs and is the most important tool in the end with which users and those responsible can coordinate and control process and production flows.

We offer a wide spectrum of competence in the field of measurement and control technology. For instance, we can check the efficiency of your plastic components and other technical elements in a fully air-conditioned room by using our stationary measuring units and a 3D coordinate measuring machine of type Fa. Wenzel. The previously specified parameters of the to be measured unit get checked as well as the tolerances within the nanostructure. We can guarantee an outstanding product quality and prevent unnecessary optimization loops thanks to such a sensor-based technology. Furthermore, we have the possibility to take CAD-based three-dimensional measurements on-site thanks to our mobile Faro Prime Measurement Arm.

We can also design and implement customized measurement systems for your serial products and production flows ourselves, for instance, in cases where a measuring device is needed for special production parts. We place the parts into the device and the sensor checks them and their efficiency by scanning their neuralgic points. After we have created a sample with standard values, we can evaluate if the production of the component was successful or if we need to sort out the component. In this way, we don’t just create a smooth and fast process flow but we also guarantee a consistent product quality. Through the aid of highly sensitive sensors we can scan each component at selected points. If parts differ from the standard size, we will repair or replace them, if necessary. We are experts in this sensor-based technology and develop individual manufactured measuring equipment solely for our clients products.

Messtechnik stationär

3D Koordinatenmessmaschine

LH87/ Fa. Wenzel

Arbeitsbereich 1000x760x660mm

Messtechnik mobil

-

- Mobile measurement technology by means of Faro Prime measuring arm

- CAD-based, three-dimensional measurement also at your site

- Software: CAM2 Measure 10 for maximum measurement efficiency

- Faro arm with 2.4m working space and a measurement repeatability of 0.02mm

Mehr Effizienz durch die Komp-

rimierung verschiedener, einzelner Arbeitsschritte zu einer kompakten Automatisierungseinheit

We manufacture customized machines and systems according to specific requirements and individual wishes, so that you get complex tasks and processes automated in one working unit. We either design and manufacture completely new machines or make extensive modifications to existing machines. We build new products completely in our own factory. We analyze the task / sample piece in advance and develop precisely fitting solutions. From single components to complete solutions, you can expect no hidden or unexpected costs. Translated with www.DeepL.com/Translator (free version)

Any questions? Ask! - We accompany you on your way to more productivity